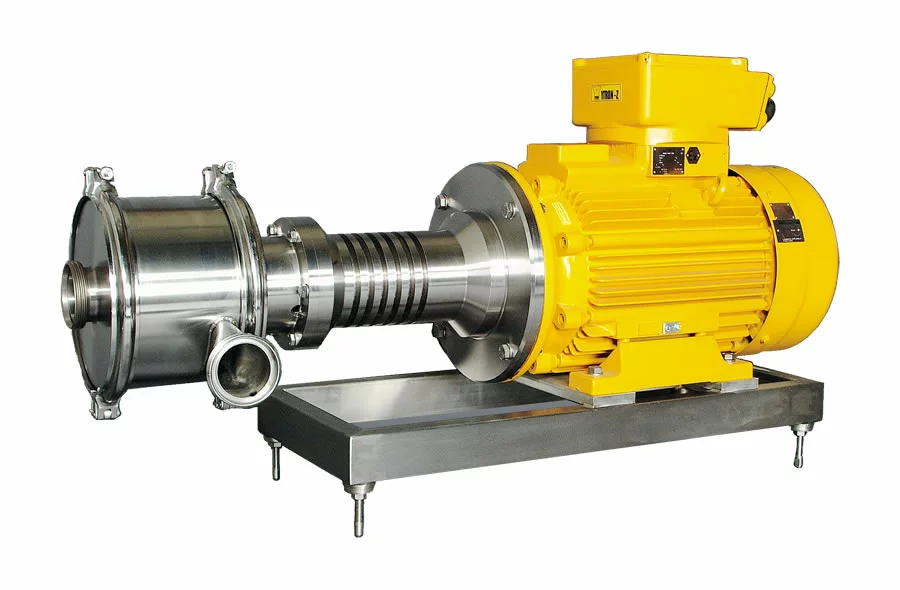

Ytron-Z InLine homogenizer

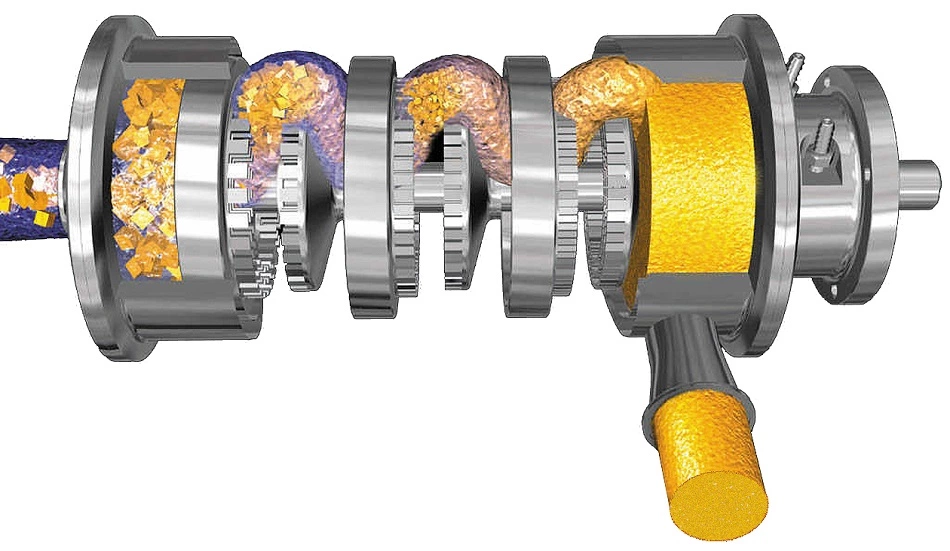

The design of the Ytron-Z homogenizer allows up to 3 sets of rotor/stator combinations in the same machine. The rotor/stator is manufactured with very high precision and with different slot openings to provide maximum flexibility. This homogenizer has many applications and transforms liquid treatment with its advanced rotor-stator system.

More information

Optimal homogenizer from Ytron

The YTRON-Z InLine homogenizer transforms liquid treatment with its advanced rotor-stator system. This technique ensures precise and reproducible application of shear forces for control over dispersion and homogenization. Central parameters such as slot width, number of slots, rotation speed and flow rate give users adjustability. Unlike conventional batch processes that over-shear and produce irregular processing, YTRON-Z produces homogeneously dispersed product in one pass.

The YTRON-Z InLine homogenizer serves for dynamic mixing, dilution, emulsification and deagglomeration. With motor power from 1.5 to 132 kW, it excels in de-agglomeration, wet milling, STRETCHING®, chemical reactions. This homogenizer is used in various industries, for example bitumen, tomato ketchup, creams, fruit juices, soft drinks, mayonnaise, medical solutions. It creates O/W and W/O emulsions, handles perfume oils, pesticides and S.L.E.S.

The benefits include improved product quality, reduced production time through one pass, reproducible results, as well as savings in energy, materials and process time compared to batch processes. Its flexibility improves rheological properties, mouth-feel and texture. The YTRON-Z InLine homogenizer is a pioneering solution for efficient liquid treatment.

Areas of use for Ytron-Z:

- Homogenization

- Merging of emulsions

- Microsuspension

- Dispersion

- Adjustment of viscosity

- “Mouth feel” improvement

- Adding of air/gas

- Stretching of Yoghurt

Do you want to read more about the product? Then download Ytrons Z productsheet